BOOK PRINTING FACTORY

Custom Book Printing

Since 1992

Custom Book Printing

Since 1992

Product details

|

|

|

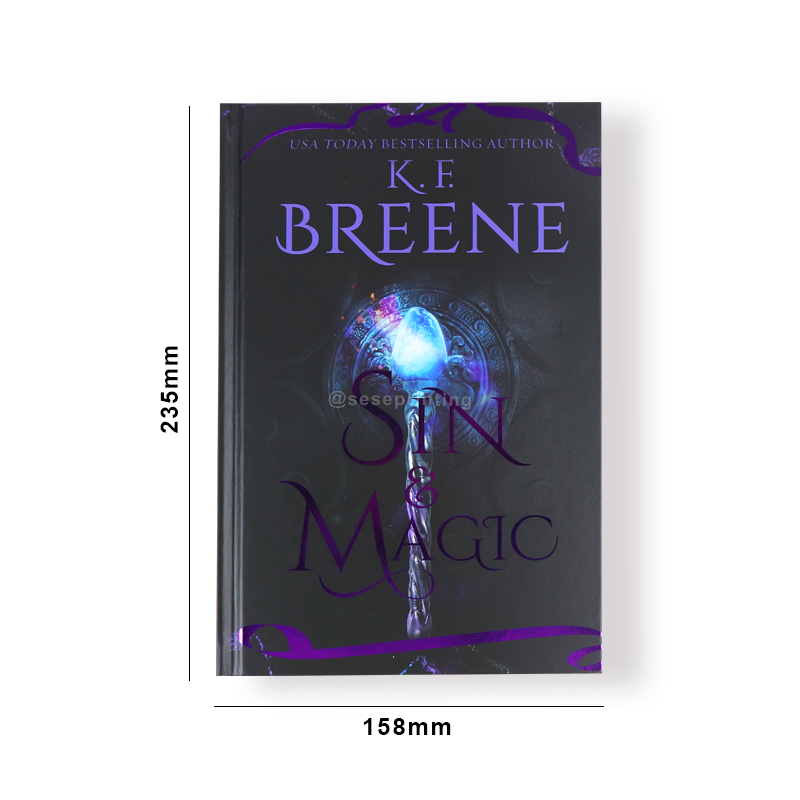

Book Size |

Black and White Printing |

|

|

|

|

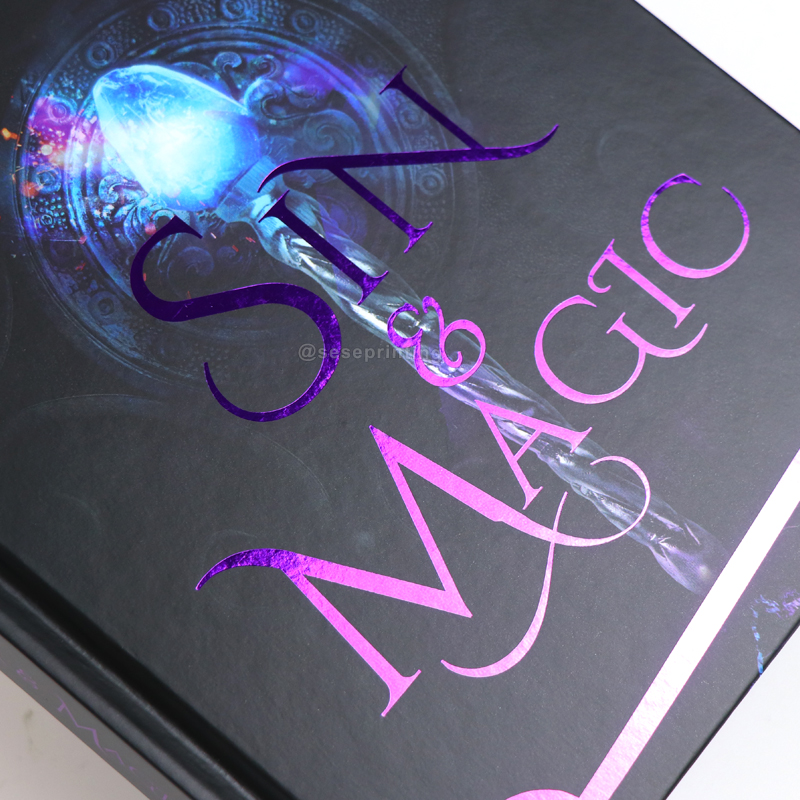

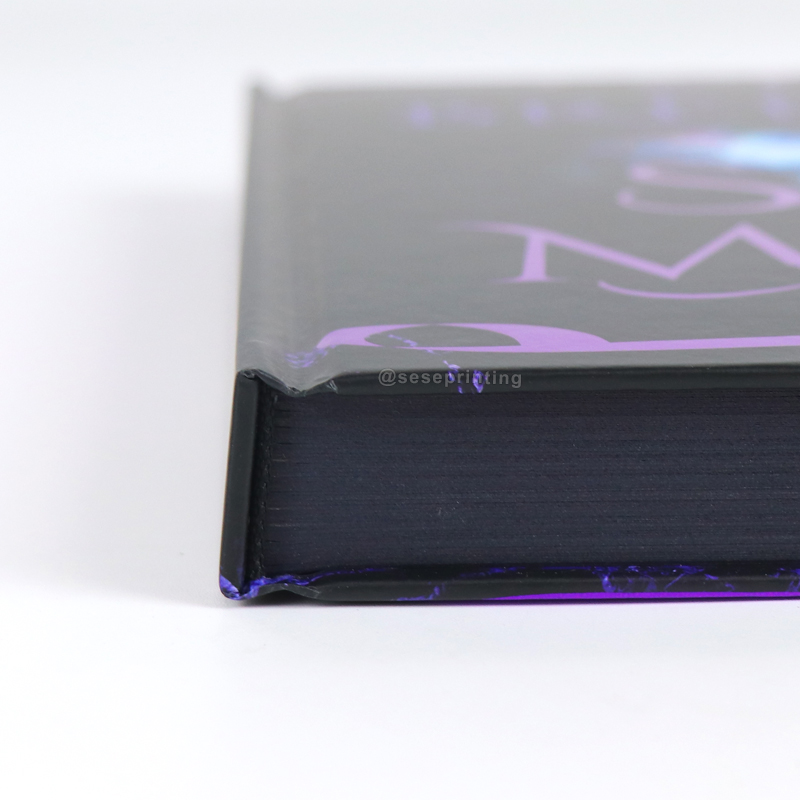

Purple Foiled on Cover |

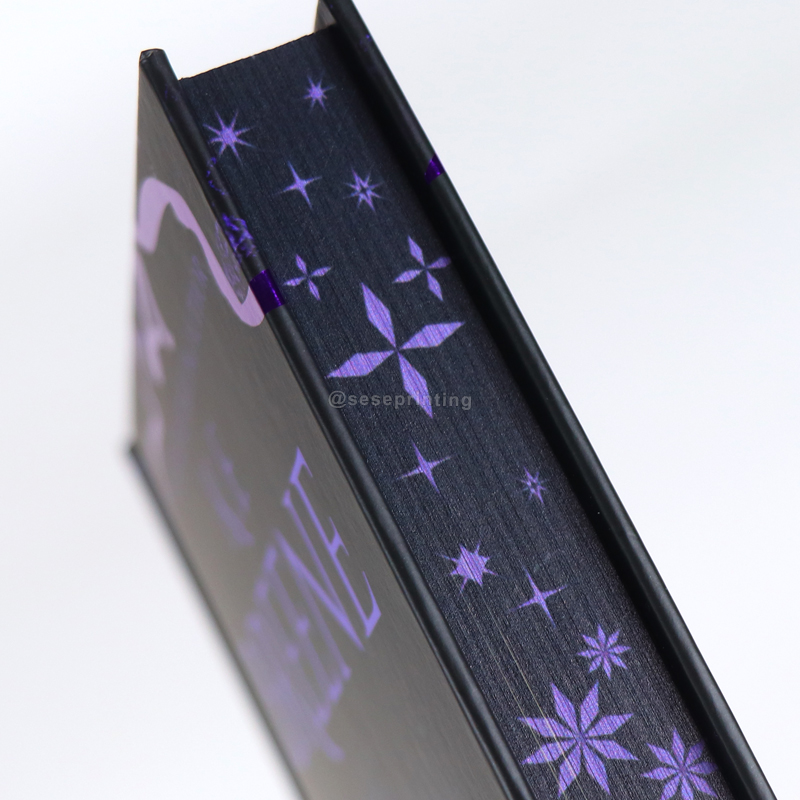

Full Color Image Edges |

Case Bound |

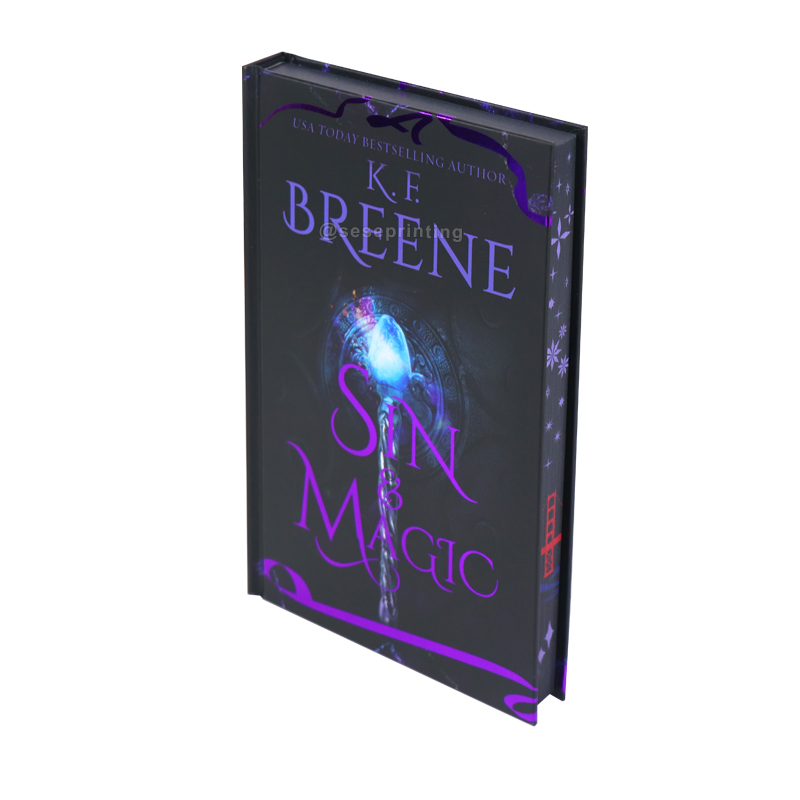

| Product Name | Sprayed Edges Book |

| Material | Glossy/Matt Art Paper, Offset Paper, Woodfree Paper, Writing Paper, Light Coated Paper, Special Type Paper, Grey Board, Kraft Paper, Coated Paper, And so On. |

| Binding | Thread Sewing Binding, Saddle-Stitching Binding, Wire-O Binding, Spiral Binding, Perfect Binding, Case Bound, Etc. |

| Certification | ISO9001, SA8000, FSC |

| Design | From Clients,OEM |

| Size | Decided by Client |

| Printing | CMYK or Pantone |

| Artwork Format | AI, PDF, ID, PS, CDR |

| Finishing | Gloss or Matt Lamination, Spot UV, Emboss, Deboss and Sprayed Edges |

Related Suggestion

Related Suggestion

Tel

Tel

Email

Email

Address

Address

301, NO.233 PingKang Road, Shiqiao St.,Panyu District, Guangzhou City, Guangdong Province, China 511400

Whatsapp

Whatsapp

Home

Home