Top 10 Questions Answered About Perfect Bound Book Printing

Aug 12,2024

Aug 12,2024

SESE

SESE

Top 10 Questions Answered About Perfect Bound Book Printing

1. What is Perfect Bound Book Printing?

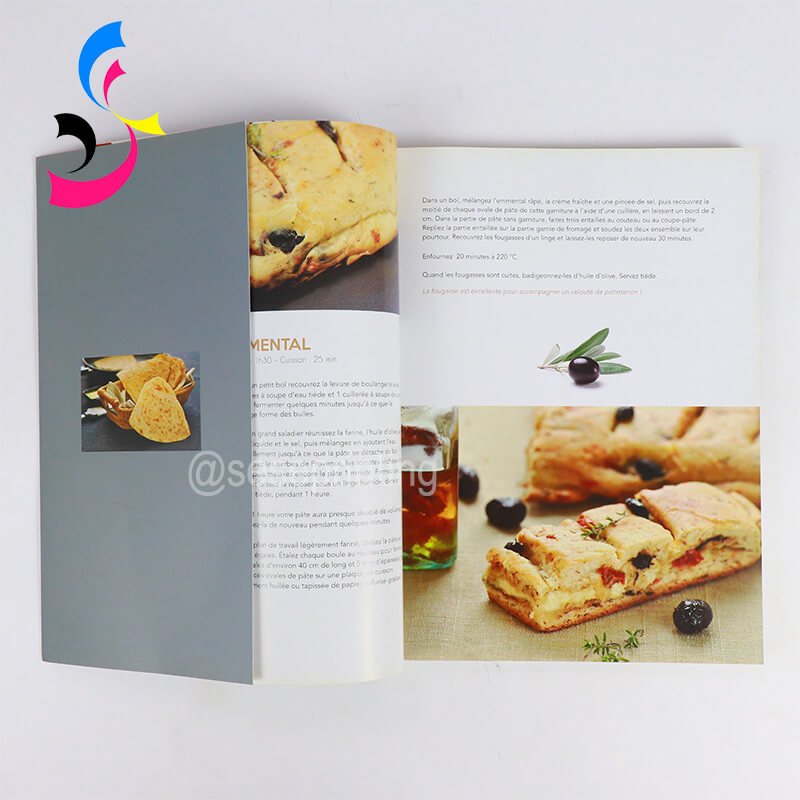

Perfect bound book printing is a popular binding method where the pages and cover are glued together at the spine with a strong adhesive. This creates a flat spine that can be printed on, providing a clean and professional look. Perfect binding is commonly used for paperback books, catalogs, magazines, and manuals.

2. What are the Advantages of Perfect Bound Books Printing?

Professional Appearance: The clean, flat spine and sharp edges give a polished look.

Durability: Strong adhesive ensures pages stay securely in place.

Cost-Effective: Generally less expensive than other binding methods like hardcover binding.

Flexibility: Suitable for various sizes and page counts.

Printable Spine: Allows for easy identification on shelves.

3. Perfect Binding vs Sewn Perfect Binding: Which One is Best?

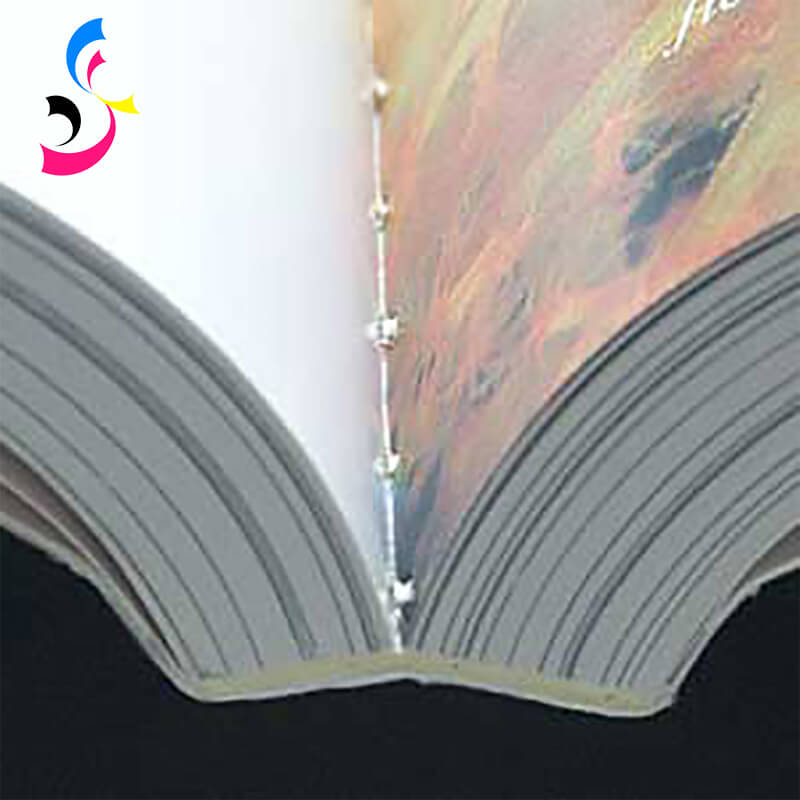

When it comes to perfect bound books, there are two main binding methods: perfect binding and sewn perfect binding. While both techniques involve gluing the pages to the spine, sewn perfect binding adds an extra step of sewing the pages together before binding. Let’s explore the differences between these two methods:

|

|

|

perfect binding |

sewn perfect binding |

Durability: Sewn perfect binding is generally considered more durable than regular perfect binding. The sewing process adds an extra layer of strength and stability to the book, making it less likely to fall apart with heavy use or over time.

Page limit: Regular perfect binding has a page limit, typically around 300-500 pages, depending on the paper thickness and book size. Beyond this limit, the book may become too thick and bulky for the binding to hold effectively. Sewn perfect binding, on the other hand, can accommodate a higher page count, making it a better choice for thicker books or publications with a large number of pages.

Cost: Sewn perfect binding is typically more expensive than regular perfect binding. Due to the additional labor and materials required for the sewing process.

Lay flat: Books bound with the sewn perfect binding method tend to lay flatter when opened, making them more suitable for reference books, cookbooks, or any publication that requires frequent referencing or note-taking. Books bound with perfect binding, usually hard to lay flat when opened, due to the pages are glued together.

Production time: Sewn perfect binding takes slightly longer to produce than regular perfect binding. Due to the additional sewing step involved.

When choosing between perfect binding and sewn perfect binding, consider factors such as the intended use of the book, the number of pages, and your budget. For thicker publications or those that require durability and lay-flat capabilities, sewn perfect binding may be the better option. But regular perfect binding is a more cost-effective choice for thinner books or publications with a lower page count.

4. How to Choose the Orientation for Your Perfect Bound Books?

When choosing the orientation for your perfect bound book, consider:

Content Layout: Portrait orientation is standard for most books, while landscape is better for wide images or graphs.

Audience Preference: Know your target audience’s preferences.

Design Elements: Ensure your design elements fit the chosen orientation without appearing cramped or stretched.

5. Can Printed Perfect Bound Books be Customized with Special Extras?

Yes, perfect bound books can be customized with a variety of special extras:

-

Book flap: A book flap, is an extension of the book cover that folds inside the front and back covers. It provides additional space for promotional text, author biographies, or other relevant information about the book.

-

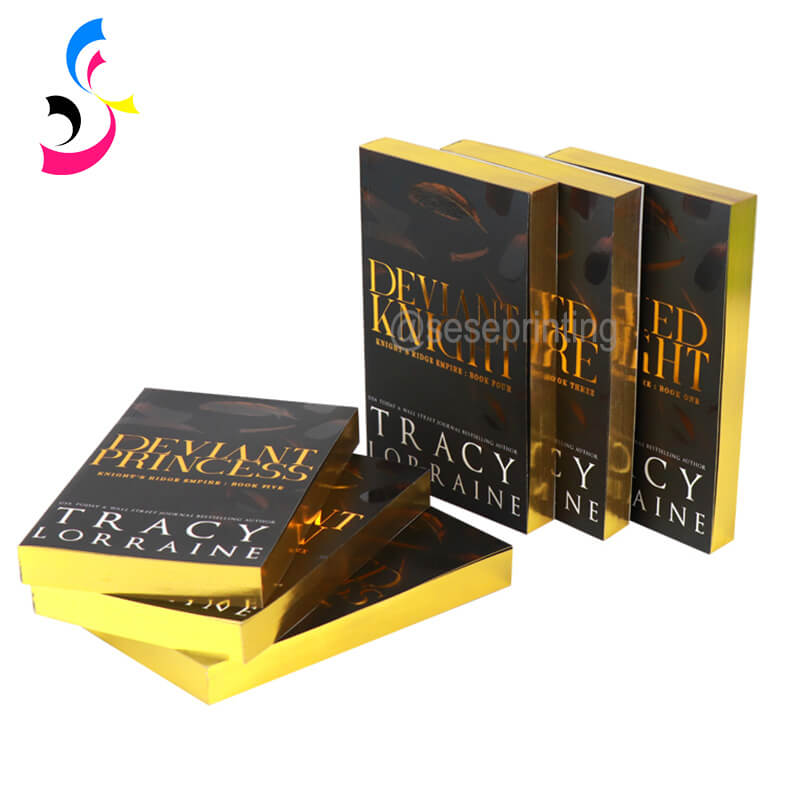

Foil stamping: Foil stamping is a printing technique that involves applying a thin layer of metallic foil (such as gold, silver, or colored foils) to the cover or spine of the book, creating a shiny, eye-catching effect. It can be used to add text, logos, or decorative elements to your book’s cover.

-

Spot UV: Spot UV, is a printing technique that applies a high-gloss, clear coating to specific areas of the book cover, creating a raised, shiny effect. It can be used to highlight text, logos, or design elements, adding depth and visual interest to your book’s cover.

-

Emboss/Deboss: Embossing and debossing are techniques that create raised or recessed patterns or text on the book cover, respectively. Embossing raises the design elements, while debossing creates a sunken or indented effect. These techniques can add texture and dimensionality to your book’s cover, making it more tactile and visually striking.

-

Glitter edges: Glitter edges involve applying a thin layer of glitter or metallic foil to the outer edges of the book pages, creating a sparkling effect when the book is closed or opened. This unique touch can add a touch of glamour and visual interest to your book.

-

Die-Cutting: Die-cutting is a precise cutting technique that involves using a custom-made die to cut shapes, patterns, or designs into the cover or interior pages of a book. This technique allows for the creation of intricate and unique designs that can enhance the visual appeal and functionality of your book. Die-cutting can be used to create custom shapes for the cover, cut-out windows, tabs, or even decorative elements that add a tactile dimension to your book’s design. This method is particularly effective for adding a creative and distinctive touch to your book, making it stand out from standard designs.

|

|

|

|

Book Flap |

Foil Stamping |

Spot UV |

|

|

|

|

Embossing |

Glitter Edges |

Die-Cutting |

6. What Factors Affect the Printing Cost of Perfect-Bound Books?

Several factors influence the printing cost:

Page Count: More pages mean higher costs.

Paper Quality: Premium paper types are more expensive.

Ink Type: Full-color printing costs more than black-and-white.

Cover Material: Special finishes or thicker cover stock add to the cost.

Print Run Size: Larger quantities typically lower the cost per unit.

Custom Features: Extras like foil stamping or embossing increase costs.

7. What are the Popular Uses of Perfect Bound Books?

Perfect bound books are versatile and used for various purposes:

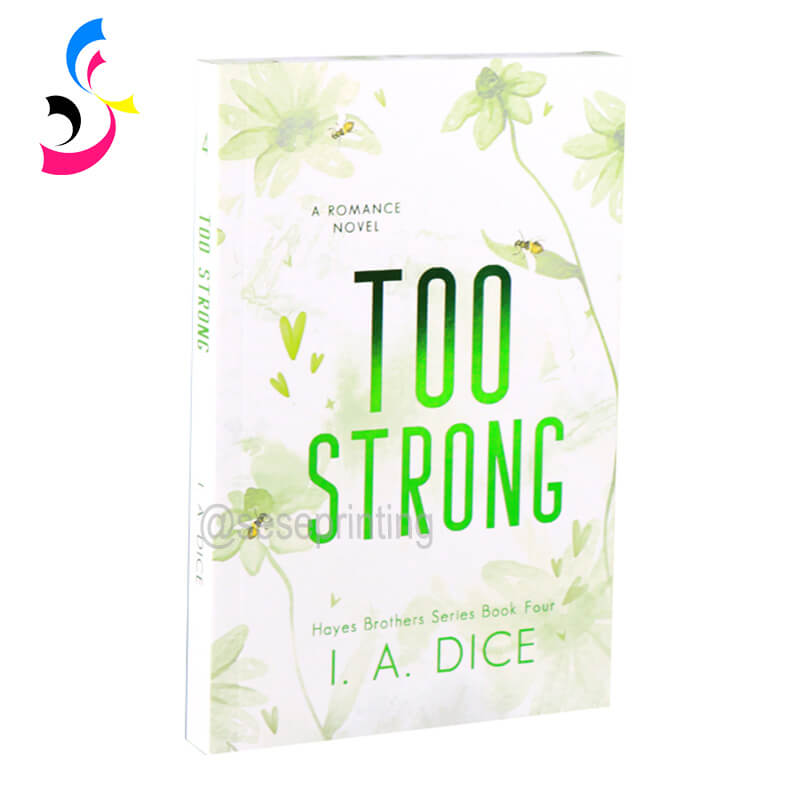

Novels and Non-Fiction Books: The polished appearance suits all types of literature.

Catalogs and Magazines: Ideal for showcasing products or content in a professional manner.

Manuals and Reports: Durable and easy to handle for informational purposes.

Yearbooks and Photo Books: Perfect for capturing memories with a lasting impression.

Educational Materials: Textbooks and workbooks benefit from the durability and ease of use.

8. How to Calculate Spine Width of a Perfect Bound Book?

Calculating the spine width of a perfect bound book is essential to ensure a proper fit and professional appearance. The spine width affects the space available for the book's title and other design elements, as well as the overall thickness of the book. Here’s a step-by-step guide to calculating the spine width of a perfect bound book:

Determine the Total Page Count:

Count the total number of pages in your book, including any blank pages, inserts, or additional content.

Measure the Paper Thickness:

Measure the thickness of the paper stock you will be using for your book. This thickness is usually expressed in inches or millimeters (e.g., 0.001 inches or 0.0254 mm).

Calculate the Book Block Thickness:

Multiply the total page count by the paper thickness to find the book block thickness. For instance, if your book has 300 pages and you’re using 80gsm uncoated paper (approximately 0.0039 inches or 0.1 mm thick), the book block thickness would be calculated as follows:

(300pages×0.0039inches)/2=0.585inches(or15mm)

Account for the Cover Stock Thickness:

Measure the thickness of the cover stock you’ll be using for your book. Cover stock is typically a heavier weight paper or cardstock.

Add the Cover Stock Thickness to the Book Block Thickness:

Add the cover stock thickness to the book block thickness to get the total spine width. For example, if your cover stock is 0.0123 inches (0.32 mm) thick, the total spine width would be calculated as follows:

Spine=Bookblockthickness(0.585inches)+Coverstockthickness(0.0123inches)=0.5973inches(or15.32mm)

It’s important to note that this calculation is an estimate, and the actual spine width may vary slightly due to factors such as paper bulking, binding techniques, and printing tolerances. Consulting with your printer and providing them with your book specifications is always a good idea to ensure an accurate spine width measurement.

Additionally, keep in mind that books with a higher page count or those using thicker paper stocks may require a wider spine width. A properly calculated spine width not only ensures a professional appearance but also helps prevent issues like text or design elements being obscured or pages not opening properly.

9. What’s the Minimum and Maximum Page Requirements for Perfect Bound Book Printing?

The minimum page count for perfect bound books is typically around 28 pages. This is because fewer pages may not provide enough spine width for effective binding. The maximum page count can go up to several hundred pages, depending on the paper thickness and the binding quality.

10. Do You Accept Custom Size Based on My Perfect Bound Book Projects?

At SESE Printing, we understand that every project is unique. That's why we strive to accommodate custom size requests for perfect bound books. We recognize that standard book sizes may not always fit the specific requirements or creative vision of our clients.

Whether you have a unique concept in mind or need to adhere to specific dimensions for your project, we can work with you to produce custom-sized perfect bound books tailored to your needs. Our state-of-the-art equipment and experienced team allow us to handle a wide range of book sizes, from miniature manuals to large-format photo albums.

When requesting a custom size, we’ll guide you through the process, ensuring that your desired dimensions are feasible and optimized for the perfect binding process. We take into account factors such as paper stock, page count, and binding method to ensure a professional and durable final product.

Custom sizes can open up new creative possibilities for your perfect bound book projects. For instance, you could create a landscape-oriented book to showcase panoramic photographs or a square-shaped book for a unique children’s story. The possibilities are endless, and we’re excited to bring your vision to life.

To initiate a custom size project, simply provide us with your desired dimensions, and our team will work closely with you to ensure a seamless production process. We’ll provide guidance on any necessary adjustments or recommendations to achieve the best possible result.

At sese printing, we believe in offering tailored solutions to meet the diverse needs of our clients. Whether you’re a self-published author, a small business, or a large corporation, we’re committed to delivering high-quality, custom-sized perfect bound books that exceed your expectations.

Don’t settle for standard book sizes that may not fit your needs perfectly. Contact us today to discuss your custom perfect bound book printing project, and let our team of experts guide you through the process. We’ll work closely with you to bring your unique vision to life, ensuring a professional and visually stunning final product. Unleash your creativity with custom-sized perfect bound books from us.

Home

Home

Book Dust Jackets

Book Dust Jackets  You May Also Like

You May Also Like

Tel

Tel

Email

Email

Address

Address