A Comprehensive Guide to Spiral Binding Book Printing

Dec 26,2024

Dec 26,2024

SESE

SESE

A Comprehensive Guide to Spiral Binding Book Printing

1. What’s Spiral Bound Book Printing?

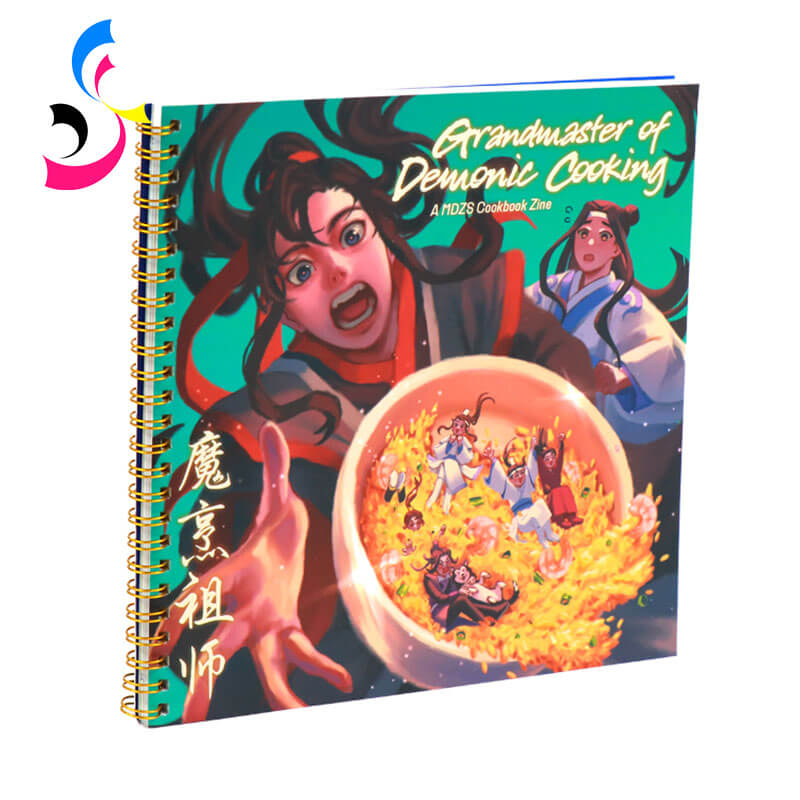

Spiral bound book printing is a method of binding books where pages are punched with holes and held together by a durable plastic or metal coil. The coil is threaded through the holes, allowing the book to lay flat or fold back on itself. This binding method is ideal for various uses, including manuals, workbooks, planners, and presentations.

2. Pros and Cons of Spiral Bound Books

Pros: |

Cons: |

Durability: Spiral bindings are sturdy and can withstand frequent handling. |

Limited Spine Printing: Unlike traditional book bindings, spiral-bound books lack a printable spine. |

Lay-flat Design: They open fully flat, making them excellent for note-taking and reference. |

Aesthetic Appeal: They may lack the professional look of hardcover or perfect-bound books. |

Flexibility: Pages can be turned a full 360 degrees for easy use. |

Page Removal: Pages can sometimes tear out if not handled carefully. |

Customization: Available in various colors, sizes, and materials to suit different needs. |

3. Materials Used for Spiral Bound Book Printing

Paper: The choice of paper varies from lightweight to heavy stock, depending on the purpose of the book. Glossy and matte finishes are common for covers and pages.

Cover: Covers can be made from cardstock, laminated paper, or even plastic for added durability.

Coils: Coils are made from materials such as plastic or metal, each offering different levels of flexibility and strength.

Finishes: Protective coatings like UV or lamination can enhance durability and aesthetics.

4. Process of Printing Spiral Bound Books

Design Preparation: Create or finalize the book’s layout using graphic design software. Ensure margins accommodate the binding area.

Printing: Print the pages and covers using high-quality printers.

Punching Holes: Use a hole-punching machine to create evenly spaced holes along the edge.

Inserting Coils: Thread the spiral coil through the holes manually or with a machine.

Crimping: Secure the coil ends to prevent unraveling.

Quality Check: Inspect the final product for alignment and durability.

5. The Impact of Spiral Binding on the Reading Experience

Spiral binding significantly enhances the user experience for practical books like cookbooks, guides, and planners. The lay-flat and fold-back design allows readers to focus on content without struggling to keep pages open. It’s especially beneficial for hands-free reading or writing tasks.

6. How to Differ Spiral Bound and Wire-O Bound?

|

|

Spiral Bound:Made with a continuous plastic or metal coil.Flexible and allows for 360-degree page rotation.Typically used for casual or semi-professional applications. |

Wire-O Bound:Uses a double-loop wire binding.Less flexible but sturdier compared to spiral binding.Suitable for professional presentations and high-end notebooks. |

|

Home

Home

Personalize Your Printed Books with Custom Accessories

Personalize Your Printed Books with Custom Accessories  You May Also Like

You May Also Like

Tel

Tel

Email

Email

Address

Address