Printing On Demand versus Offset Printing

Jul 10,2018

Jul 10,2018

SESE

SESE

Magazines and Catalogs have always been powerful marketing tools for brands and enterprises. Even in today\'s e-business world, companies like anthropology and Patagonia rely on printing materials to attract customers and redisplay their brands with amazing visual effects and fascinating stories.

Positioning your catalog or magazine as a marketing tool starts with yielding the most value out of your print dollar. Often the biggest question you’ll face is deciding between printing print-on-demand and offset printing, We’ll walk you through what you can expect from both these options in terms of quality and budget.

What\'s the difference between printing on demand and offset?

Digitally printed, on demand printing is a convenient and flexible printing process, printing very much like your printer at home. Few (if any) requirements are required, and the installation cost of on-demand printing makes it easy to quickly execute and distribute print items. On the other hand, offset printing uses large printing presses to transfer ink from the customized version to the big page, called master plate. These tables are then cut and bound to create the project. Offset printing requires higher installation costs, but we will outline the following ideal choices for higher quality projects.

What will the color be?

The application process of on-demand printing and offset printing is completely different, which directly affects the appearance of the project. Use of toner in demand printing and the fusion of powder with paper coating during printing. On the contrary, offset printing transfers the real ink to four layers of color: blue, horse, yellow and black. Each color needs its own customized metal plate, which is why this process takes a week. Unlike on-demand printing, offset printing technology is ideal for photo, drawing and rich vision, because it prints the degree of color and can\'t compete on demand printing. If you are interested in black and white printing, on demand printing is still a good choice, but it will lack the depth of color that offset itself brings.

What about the material and the binding?

The process of ink application also directly affects the type of paper that can be used for printing and offset printing. Due to the use of toners, paper on demand must be glossy and glossy. On the contrary, the paper used for offset printing absorbs ink, increasing the number of materials selected for your project. For example, if you are looking for a complex, lustrous feel, uncoated paper is provided, offset printing is the way to go. Offset printing can also be adapted to irregular paper size, which is contrary to the way you print on demand.

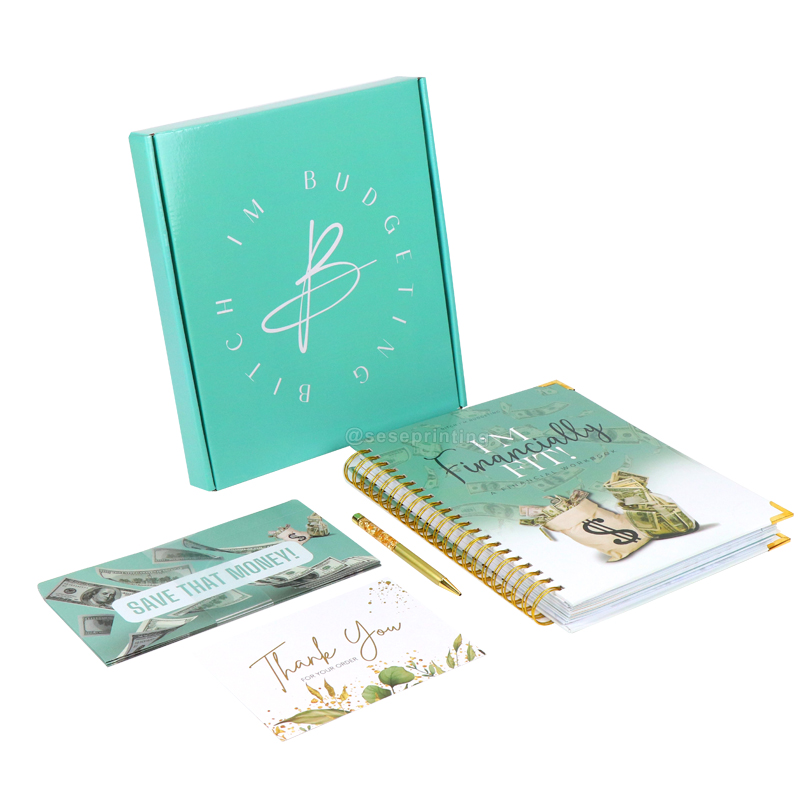

On demand printing can also restrict your binding options, because many manufacturers only provide saddle stitching, folding or staple binding. Offset printing can open doors with higher quality binding options. Primtnina provides a perfect bundling directory, where the web pages are collected, sutured, and then glued into a cover to create a solid, square spine that won\'t collapse during transportation.

What makes sense to you?

If you don\'t know how many copies you need, print on demand and print it quickly. Similarly, on demand, you can print more instantly as needed, but this advantage is running in more than 500 copies. After this threshold, although it takes longer, offset printing is more cost-effective than each unit, especially in 500 to 1000 units. Similarly, creating a look and feel professional product requires a convenient offset printing technique.

Home

Home Custom Children Book printing From China

Custom Children Book printing From China  You May Also Like

You May Also Like

Tel

Tel

Email

Email

Address

Address