Our factory has passed ISO9001:2008, Disney Audit, Sedex certificate, BSCI certificate, FSC and SGS test to raw materials like ink. So you are very safe to print with us.

Yes, we can ship the goods to your office directly, actually it is the DDU cost which means door to door. The DDU cost will be included all the cost from our factory to your office.

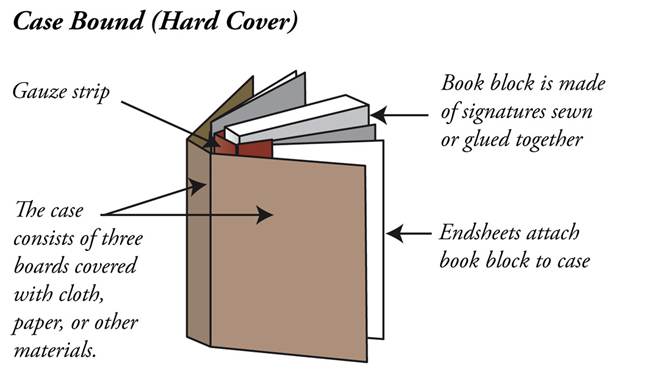

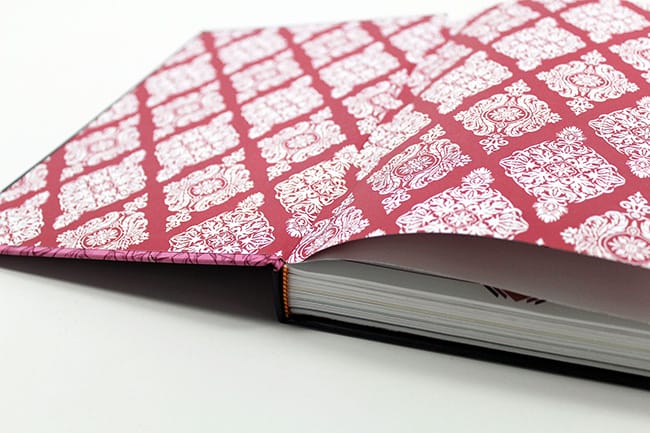

The end paper means the paper mounted on the inside font and back cover, usually it has 8 end pages for hardcover books.

RGB is a color spectrum that consists of Red, Green, and Blue—this spectrum should be used for digital files.

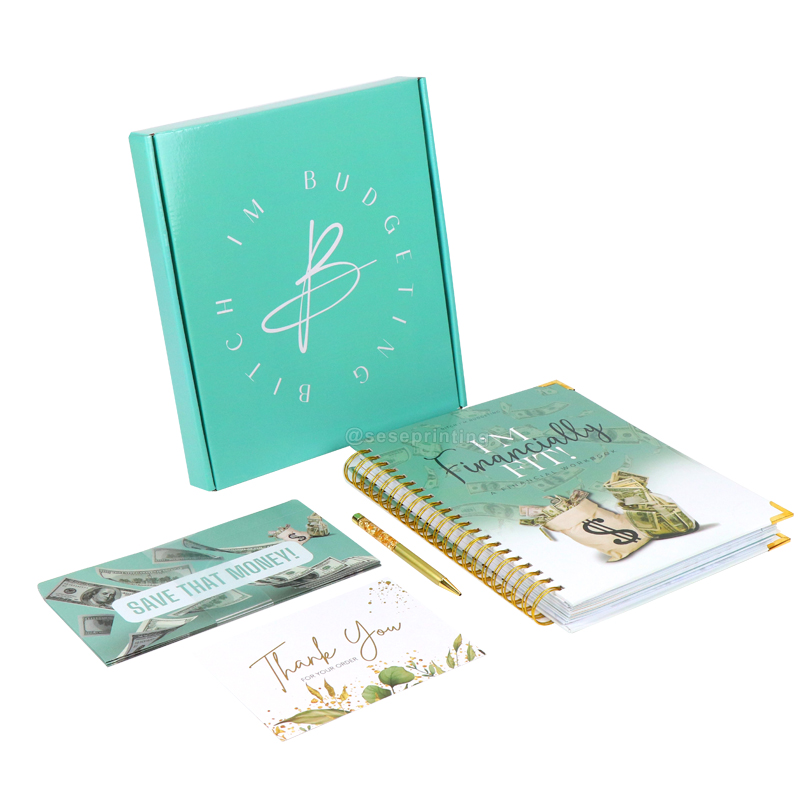

We only accept fully customized and artwork printing, so we do not have the existing products to sell.

If you receive your books and feel that they are unsaleable for any reason, you must contact BookPrinting.com in writing (including images to illustrate your concerns) within 10 business days of accepting delivery of your order. We will review the damages and proceed accordingly, assisting you with processing damage claims—either with the printer or the shipper, depending on where the damage seems to have originated.

Our products can be customized as the customer’s requirement.(include logo, color, size etc.)

In order to quote you an accurate price, pls kindly advice answers as below :

1. Quantity:

2. Size: Length*Width* Height(if you don’t know the size, please kindly let me know your product size, we can suggest suitable dimension for you)

3.Usage: What kinds product will packaging

4. Material: we can suggest the material for you according to your products.

If you have any question about the detailed information, we can advice to you also.

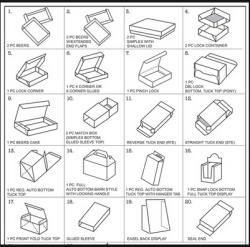

For the tuck boxes and cigarette boxes, we usually used the one side glossy art paper or card paper; for the top and bottom boxes and book shape boxes, we usually used the 157gsm glossy art paper mounted a greyboard.

The paper playing card has two standard size of the cards: 57*88MM or 63*88MM.

Guangzhou SeSe Printing Co.,LTD is a China based book manufacturer who specializes in providing a wide range of custom book printing services. Taking advantage of our almost 30 year’s book printing experiences, we could provide clients flexible solution at competitive factory price.

Our factory has passed ISO9001:2008, Disney Audit, Sedex certificate, BSCI certificate, FSC and SGS test to raw materials like ink. So you are very safe to print with us.

In making your book, we need a little bit extra image on your cover and anything in your text that you want to end at the far side of your page, to ensure that color will show up all the way around the page. For example, if you have a picture that covers one whole page and you do not want any white showing, we need you to either make the image slightly bigger than the page or add color to the sides of the page. We ask that you do this so that we can get a good trim on your book, have color on every edge and to make it as close to the size as you want it to be. We run your text, in most cases, four-up to minimize cost and then cut the four down to individual copies which will then get bound to your cover.

Space frame has excellent performance which is much better than other steel structure. If the span is more than 30m, space frame is more economical, safer , and with better seismic performance. So it becomes widely welcomed by the clients nowadays all over the world.

The main advantages are as following:

The span of space frame can be very big without columns in the middle to support the whole structure, so space frame structure is suitable for buildings covering large area.

Cost of space frame

Generally speaking

If span≥30m, the cost of space frame is lower than the other structures.

If span <30m & ≥20m, the cost of space frame is almost same to other steel structures.

If span <20m, the cost of space frame is higher than other structures.

Space frame structure has light self-weight.

Space frame structure is safer than other traditional structures.

Space frame has excellent seismic performance.

Space frame is easy to install.

Space frame looks more beautiful.

Space frame structure is easy transport, as the sizes of components are small.

Space frame can be used to all kinds of building

Space frame can be produced industrially.

Many kinds of roof material can be used to space frame.

Space frame is a new type of roof truss load-bearing structure, and it is multiple statically indeterminate structure system. Space frame structure is a spatial structure connected by several pipe and node ball upon some regular pattern of geometric figure. It changes the ordinary frame structure of the general plane stress state, and it can bear the loads from all sides, even though the individual pipe in damage, it can automatically adjust the member forces, to maintain structural safety.

Steel structure is classified by structural material; space frame is classified by the structural form.

Space frame materials are steel, aluminum alloy, stainless steel, etc., in the practical use, steel is mainly used.

Space frame structure can be used for the roof or wall as the following building:

Coal storage of power plant

Cement warehouse

Stadium

Industrial workshop

Large restaurant

Train station waiting hall

Bus station waiting hall

Airport terminal

Gas station

Material conveying trestle

Exhibition hall

Canopy

Large conference hall

Movie theater

Music Hall

Aircraft maintenance hangar

Toll station

Open coal yard wind wall

Day-lighting hall of Large office building

Telecommunications tower

5-1/2" x 8-1/2" is probably the most popular size, but 5-1/4" x 8" also works for these books. Memoirs are similar sizes. Longer novels move up to 6" x 9" to avoid becoming overly bulky.

Please send us the artwork files through Dropbox, Wetransfer or http://www.hightail.com/ , both of these are okay.

And the DPI of the artwork must be reach at least 300.

It will be better if you can send us the artwork by PDF format, but it is okay with AI format too.

We can ship the goods by boat or by air. If the total weight of your goods are very heavy, we suggest you to ship by boat, if not, we suggest you to ship by air.

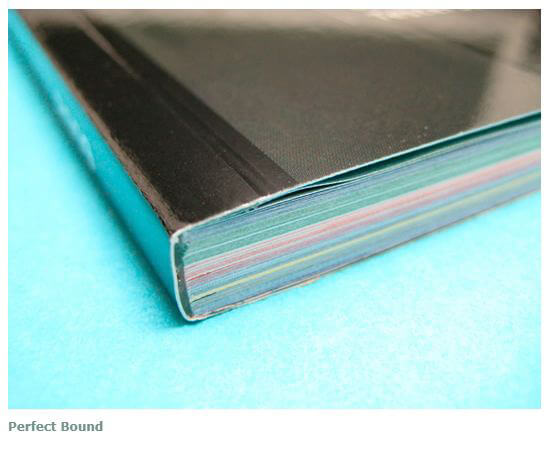

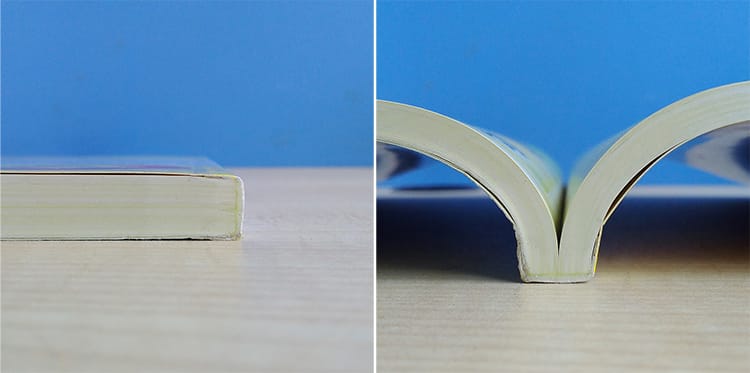

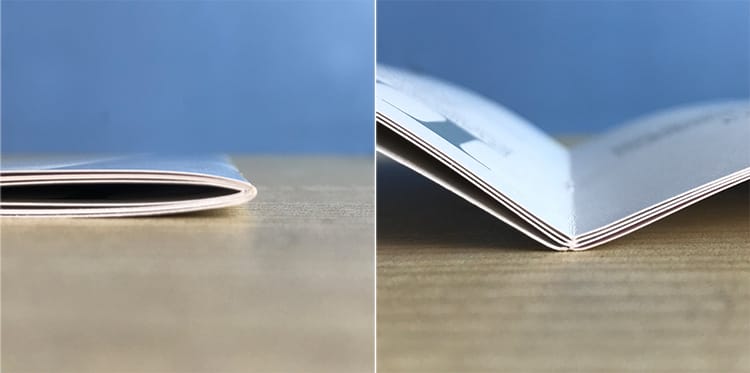

Perfect binding is the type of binding found on most soft-cover books on book store shelves. The pages and cover are glued together at the spine and the other three sides are then trimmed so that you end up with perfect edges. It has a very professional appearance and is relatively inexpensive to produce. The square spinal edge allows the book’s title and related information to be printed on the spine providing highly visible branding of the document.

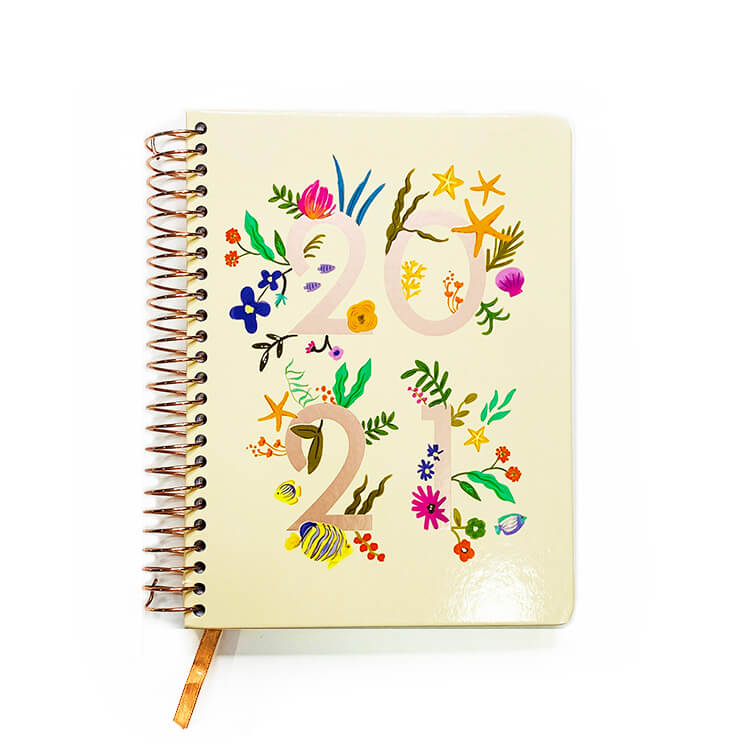

We offer a full range of bindings including saddle stitching, perfect bound, flexibound, smyth sewn, side sewn, lay-flat, glue binding, hardcover case bound, coil bound and wire-o bound. Visit our binding options page for more information.

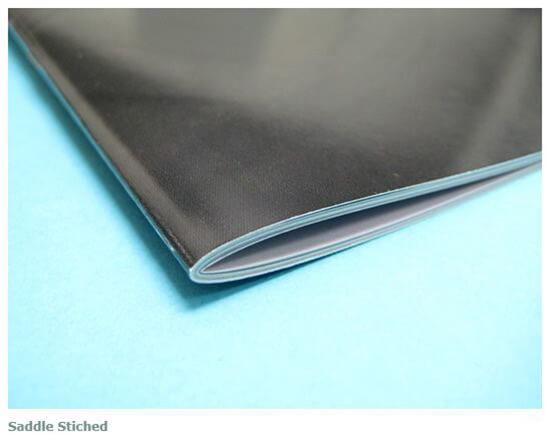

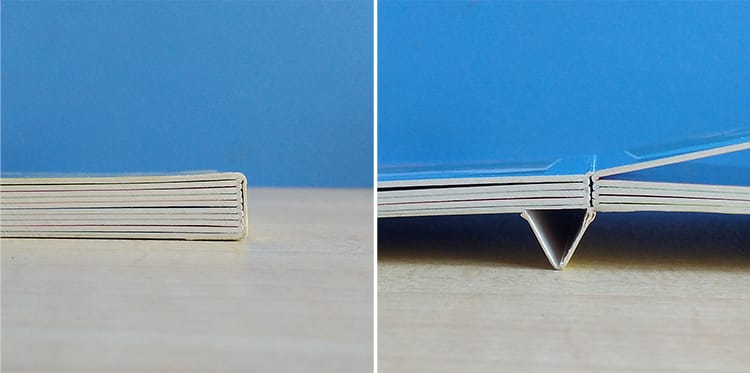

By its nature, saddle stitching requires the book’s page count to be in multiples of four. Keep this in mind during your book layout to avoid any unplanned blank pages. The saddle stitching bindery operation occurs after the pages and cover have been printed, partially folded and settled together. After being joined by staples, the cover and pages of the book are folded tighter together. Some thicker saddle stitched books are trimmed along the edge opposite the spine to keep the pages uniform and neat in appearance. Saddle stitch is most commonly used in:

Programs

Wall calendars

Booklets

Newsletters

Pamphlets

Comic books

Thinner magazines

Catalogs

Can I get custom size notepads?

Sure, we can produce almost any size or shape notepad you want.

What are the standard sizes of notepads?

The most popular standard size notepad is 5.5 x 8.5 inches, followed by 4.25 x 5.5 inches, then 8.5 x 11 inches.

What kind of papers are used with notepads?

We have a variety of standard papers listed below that are selectable on the ordering page, but any custom, recycled, premium or specialty paper can also be used.

How many sheets of paper are commonly in a notepad?

25, 50 or 100 sheets are most popular, but we can make them any count you need. Different paper stocks have varying thicknesses, so you should decide on a thickness and then we can figure out the number of sheets that will equal that thickness, either with or without a chipboard backing.

Can I use a backing sheet other than chipboard?

Sure, we can use whatever you want for the backing material, including a sheet with printing on it. You can also have a custom cover as the top sheet of the pad.

Can I have the padding on the side instead of on the top of the sheets?

Yes, the padding can be on any side of the sheet that you prefer.

What custom printing options are available on notepads?

foil stamping, Round corners, drilled holes, Pantone color inks, perforations, and custom die cut shapes are just a few popular options that turn notepads into a memorable reminder of your brand, like a tiny billboard right on a customer or prospect\'s desk.

Can my image bleed off the edge of the notepad?

Yes, it can bleed off any or all sides. Please include a 1/8" bleed in your graphic design file.

Glossy paper will bring the full color design bright and shiny, matt coated paper will bring the color rich, but not so shiny like glossy paper so it protect the eyes. Woodfree paper suck the ink more than art paper, but it is good for writing. So if the booklet/brochures are for promotional, we suggest to use glossy or matt art paper, if you need to write on the paper, it is good to use woodfree paper. There another option is light weight coated paper. Which is cheaper than glossy art or matt art paper. That is usually used for cheap booklet or brochures production.

You may contact us through the following phone numbers and email.

Tel:+86 3461-3569

Mobile:+86135-7091-2663

E-mail: sales01@seseprinting.com / enquiry@book-printing-factory.com

How to Add Bleed Marks to Inkscape. When designing a document in Inkscape, you may want your design to run right up to the edge of the printed page.

For the cover, we usually used the 157gsm glossy/matte coated paper mounted a greyboard. For the inside pages, it usaully has two different paper: coated paper or uncoated paper.If you want the coated paper, we suggest you to use the glossy or matte coated paper. If you want the uncoated paper, we suggest you to use the offset paper. Of course the paper weight is totally according to your requirements.

There are folded box & rigid box, and rigid box is higher cost than folded box. Here please kindly find below box type options for your choice. Then we could quote you immediately.

Photos or scans should always be saved as CMYK. All scanned images should be of a professional standard. Images need to be saved at an appropriate resolution of 300 dpi or above for continuous tone reproduction (photos and/or illustrations).

There are 2 common sizes: 2.5”x3.5”; 2.25”x3.5” Which size you need? If your quantity is big enough, we could also customize the cards with your own sizes.

The advanced samples will be took from mass production .So the time will be almost same as the final mass production time. Usually, it will be 3-4 days earlier than whole order is finished.

A paperback is characterized by a thick paper or paperboard cover, often held together with glue rather than stitches or staples. The standard specifications for a paperback are as follows: Text pages: Digitally printed with 1/1 black ink on 50lb uncoated white offset paper. Cover: Digitally printed 4/0 color outside on 12pt coated cover. Cover Finishing: Glossy lamination.

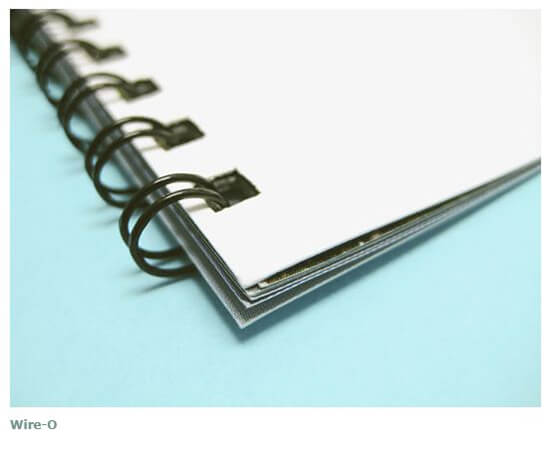

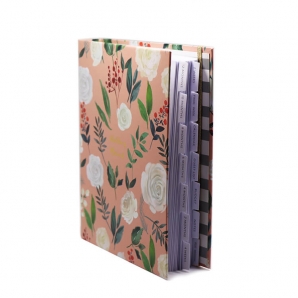

2) Wire-o binding can accommodate low page counts or high page counts. Wire-o loops come in a variety of sizes to accommodate books of varying thicknesses. The more pages the book has, the larger the wire device and loop diameter must be for proper function and aesthetics. In addition to the natural metal color of silver, wire-o binding is also available in certain painted colors.

3) The pages turn easily and stay put. When opened, the pages of a wire-o bound book rotate around the wire loops with very little resistance. So, unlike a perfect bound or saddle- stitched book, the pages of a wire-o bound book have no spinal tension in them.

4) Wire-o binding works well with index tabs. Because the wire-o binding method allows pages to turn freely and stay put without the need to manually hold them open, it is often the best choice for bound projects that require tabbed page dividers. Dividers with printed tabs are the perfect complement to any reference document – such as a reports, presentations and training manuals. directory, etc.

Q: Can I have some samples to test or make my own samples?

A: Of course you can. We have 3 options for samples.

1.Free samples of our previous card decks are available, you only need to pay the shipping cost.

2.Digital print samples: uncut sheets with your artwork

Including card face, back and tuck box, digital samples color can only be matched with offset print about70%-80%.

3. Formal sampling (physical sample). Same as product, sample color can match with product color about 90-95%

Q: What is your MOQ? Can I make cards under your MOQ?

A: Our MOQ is 1000 decks for one version.

Yes, we can make game cards under 1000 decks as requested, but the total cost is same as 1000 decks, which makes each deck very expensive and that’s why we strongly recommend you order 1000.

Q: By making custom playing cards, which part can be customized?

A: Our custom playing cards can be printed with your design on single or both side, also including the tuck box surface, CMYK printing. We offer PMS printing with extra charge.

Q: What file format shall I use?

A: JPG (Minimum 300 dpi ), PNG, PSD, PDF, AI.

Q: Do you offer artwork design service?

A: We currently do not provide a complete design service, but we can help you add some simple design or logo on the playing cards, and our in-house artist can give some suggestion for the layout.

Q: How long does it take to receive my order?

A: Normally orders under 10,000 decks, it takes 14-18 days for production after confirmation of final e-proofs and receiving deposit. To make sure you receive your order in time, please advise the delivery time so we can arrange it, even for urgent orders.

Q: Do you ship/deliver internationally?

A: Yes! We ship almost everywhere around the world. We offer DHL, Fed-ex, UPS, air and ocean shipment, let us know your shipping address so we can check the cost for you.Chin

Art paper are widely used in the advertising sector, because it gives the high printing quality. The color of the original picture can be accurately reproduced on the paper bag. There are gloss art paper and matt art paper based on the finish. The solid bleached board, also called ivory board, are thicker coated paper with the grammage higher than 160gsm-180gsm. It has the better printing quality than art paper, and more durable. While kraft paper bag are used when people has a high requirement for the loading bearing, and a not high requirement for the advertising effect.

For the paper bag rope, there are contton string, twisted string, PP string, Silk String, PP webing robe, ribbon, PVC tube, twisted paper string and leather rope.

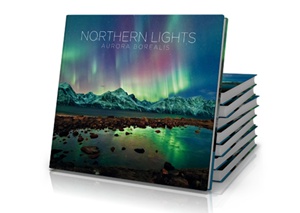

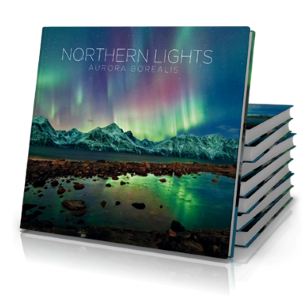

Coffee table books are predominantly oversized, heavy, hard-covered books that sit out on a, you guessed it, coffee table. Traditionally they consist of photographs, illustrations, art, and the like, with small amounts of text. Since coffee table books are more prominently displayed than your collection of novels – that you haven’t read yet – they’re seen as fodder for conversations with those you invite into your home. While these books have specific subjects they are aimed to inspire any individual.

Coffee Table Book

Binding: Case bound (hardcover)

Size: Oversized (larger than 8.5 x 11)

Cover Finish: Gloss lamination

Interior Paper Weight: 105lb text

For a heavier book use 135lb text

Interior Paper Coating: Gloss

Dust Jacket

We\'re in the midst of a self-publishing revolution, as every day more children\'s book writers and illustrators are choosing to print their own books and forego the traditional publishing houses entirely. Self-publishing gives creators freedom and creative control, but it also brings new challenges, which Sese was designed to solve.

Here\'s a list of our standard binding methods and their intended use and any limitations. Our quote form will only give you options based on your books specs, so you may not see all of these listed.

The paper that we use is called “black liner board.” The paper consists of three layers – a laminate of two layers of paper, along with a center layer of black carbon.

Also, we have several playing card stock options depending on your needs – everything from 280 gsm to 330 gsm paper or 100% plastic or transparent. Just let us know what you need.

Poker cards are a ¼ inch wider than bridge cards.

Bridge card size: is 3.5 inches high and 2.25 inches wide.

Poker card size: is 3.5 inches high and 2.5″ inches wide.

1:paper stocks(GSM) cover+text

2:size(width*length)

3:pages

4:Color

5:Quantity

6:Binding

7:Shipping address

Once get your complete info. To our email enquiry@book-printing-factory.com our sales team will reply you price promptly.

We offer coated papers, offset paper, wood free papers… We will assist you with different weights and coatings. Once we are in touch via email or telephone we can learn more about your project and offer paper recommendations fit for your quality book.

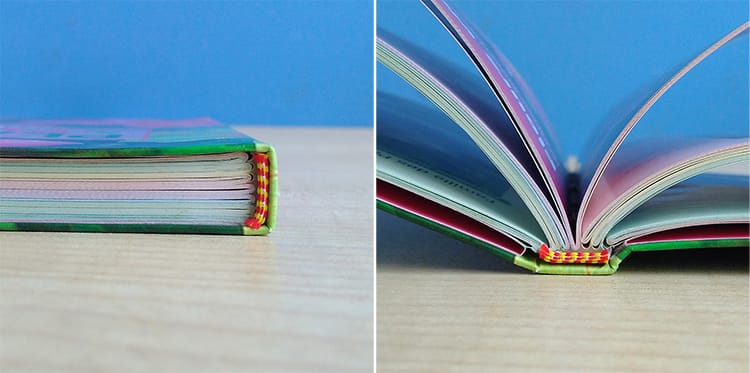

Smyth Sewn & Case Binding

Perfect Binding

Saddle Stitch/Wire Binding

Wire-O Binding

Spiral Bound

Concealed Wire-O

Sewn and Perfect Binding

Bleeds are required in all artwork with an image that extends the trim edge of the product. Add 3mm to each side to allow for cutting. For example, for a 90mmx50mm business card with full bleed, the image size should be submitted at 96mmx56mm.

For printed images, the resolution is 300 dpi. Your document size has to be 300 DPI for perfect final print results.

AI: Adobe Illustrator

PSD: Adobe Photoshop

PDF: Portable Document File

EPS: Encapsulated Postscript

INDD: Adobe InDesign

JPG/JPEG: Joint Photographic Experts Group

PNG: Portable Network Graphics

Offset printing is ideal when you need large quantities and/or flexible color, paper and sizing options. Digital printing is ideal for lower quantity projects, and when you need a quick turnaround. We will work with you to select the print method best suited to your project and budget.

Shipping

We use several different shipping methods depending on the nature, size and urgency of the job. In Canada and the USA we

typically use courier (FedEx, DHL and UPS) - or truck delivery for larger orders. For international shipments shipping costs and

service availability may mean that standard air shipment or ocean shipment is the best option.

DHL, TNT, FedEx & UPS

A signature may be required upon delivery (at the discretion of the carrier's delivery driver and depending on your location).

You will receive a tracking number once your order has shipped. Delivery time is generally 1-5 days depending on destination.

Delivery via truck

The average delivery time is 2 to 10 days depending on destination. There is no tracking number with this service however you will

receive periodic updates from us via email.

Airmail

The final delivery from this service is by the post service of that specific country. There is no tracking number with this service

however you will receive periodic updates from us via email. Average delivery time is generally 2-6 weeks depending on destination.

Ocean shipping

We are experienced in arranging logistics services to overseas destinations via ocean shipping to local port including CIF shipment

(Cost, Insurance & Freight). We are also experienced with the process of customs clearance and arranging a courier service that

delivers directly to your door (DDP shipment: Delivered Duty Paid).

We will utilize the combination of Vessel, Train and Truck for the most cost-effective solution for product delivery. There is no

tracking number with this service however you will receive periodic updates from us via email. Average delivery time is generally 5-6

weeks depending on destination.

Shipping destinations

We ship worldwide with the following exceptions.

Please contact us if you have any queries.

All book printing files must be in Adobe PDF format, all content pages combined into 1 pdf file and cover file submitted separately.

Please review the following specifications before submitting your artwork. If there are difficulties complying with the requirements,

let us know and we will try to assist you.

- Spine Width: Contact us for exact measurement according to your page count and paper stock. Hardcover book will require minimum 8mm when less than 24 pages.

- Color Mode: Color in CMYK, images with minimum 300dpi.

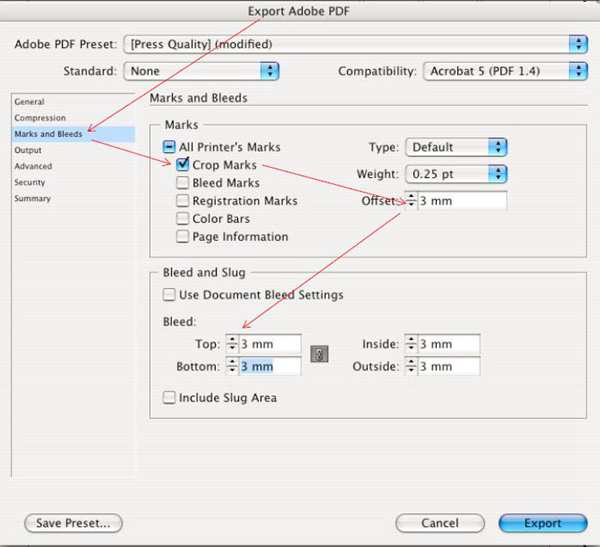

- Marks & Bleed: The bleed requirement will be minimum 1/8 inch or 3mm (preferably 1/4 inch or 6.35mm). If artwork has no bleeds, no bleed margin is required.

- Gutter or Margin: No spine gutter is required for inner pages of casebound smyth sewn books (layflat). For perfect bound (paperbacks) or limp bound books, leave minimum 1/2 (0.5 inch) to 1" (1 inch) gutter/margin around the edges of the book

- Page Spread: Page spread must be designed in single page reading spread (pg1, pg2, pg3 etc). The only acceptance for full spread (pg1&pg2, pg3&pg4, pg5&pg6 etc) will be for hardcover books or magazines with layflat finishing.

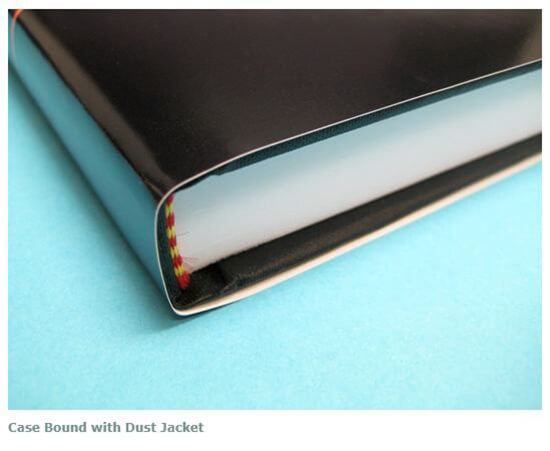

- Cover & Dust Jacket: Submit the cover artwork or dust jacket artwork separately (if there is dust jacket for the book). Front cover, spine and back cover compiled into 1 page. Contact us for exact measurement and templates according to your book size and spine thickness. We are also able to assist you if there are difficulties to comply with the file requirements.

- Text Safe Area: To avoid having text cut off during trimming, leave about 1/4" (0.25 inch) to 1/2" (0.5 inch) away from the edge of your document.

- Trimming Tolerance: Make sure to give the book design a tolerance of at least 2 mm for trimming.

- Converting to PDF: When converting to press quality PDF from a typical multi pager layout software such as Adobe Indesign, ensure the following applies to the Export settings:

BEFORE SUBMITTING YOUR FILES PLEASE REVIEW THE FOLLOWING FILE SPECIFICATIONS:

Bleed: A bleed is an extension of your background color or image going beyond the intended trim size of your piece. Please make sure your artwork has at least 1/8 inch (3 mm) margin of bleed. This ensures that the color

or image continues to the edge of your piece. Please build your press-ready digital files by adding 1/8 inch or 1/4 inch all around dimension for all products. If your artwork has no bleeds, no bleed margin is required, leave

it as the final trim size.

Colors: All colors in your document must be CMYK. If you use spot colors in your design please convert them to cmyk before saving. If your job requires pantone color (ie: 4 + 1 or 4 + 2 jobs), save the document in CMYK

plus the spot color(s). If you have difficulty converting from RGB to CMYK, let us know and we will process the conversion, however exact color match is not guaranteed.

PDF - all fonts should be embedded in PDF files

EPS - all fonts should be converted to paths or curves in EPS files

PSD - all layer must be flatten

Image Quality: Photos or scans should always be saved as CMYK. All scanned images should be of a professional standard. Images need to be saved at an appropriate resolution of 300 dpi or above for continuous tone

reproduction (photos and/or illustrations).

Text Safe Area: To avoid having text cut off during trimming, make sure that no text is within 1/4" (0.25 inch) from the edge of your document.

Bindings

Ideally, a book is something to be treasured by readers for years—read again and again over time. A beautiful and durable binding ensures your book will last. Whether hardcover or soft, we’ve got the perfect binding option for you.

Perfect binding | Hardcover Casebound |

|

|

The standard choice for most softcover books. This flexible, glued binding will stand the test of time. | Case binding provides an elegant look with more durability than a perfect bound book. Pages are commonly Smyth sewn bound which allows the pages to lay flat, without havinga gutter in between the 2 page spreads. |

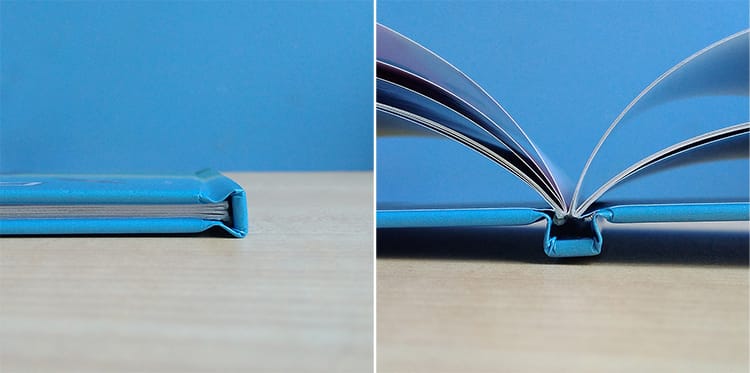

Flexi Bound | Saddle stitching binding |

| |

Flexibound offers a higher perceived value than a traditional paperback and has better protection for the inside text pages. It is commonly bound with Smyth sewn for layflat ability. | We offer perfect bindings for page counts over 16, while most other printers have a minimum page count of 64. A perfect binding is a more durable option for paperback children’s books. |

Wire-O-Bound | Hidden Wire-O Binding |

|

|

Wire-O Binding, also known as Twin Loop, Double-Loop, Double-O, Duo-Wire, or simply Wire Binding, is an attractive method for joining the pages and cover of a bound document. | The book is bound with either wire-o or coil binding and concealed with hard covers. The spine can be finished with a square or round back. |

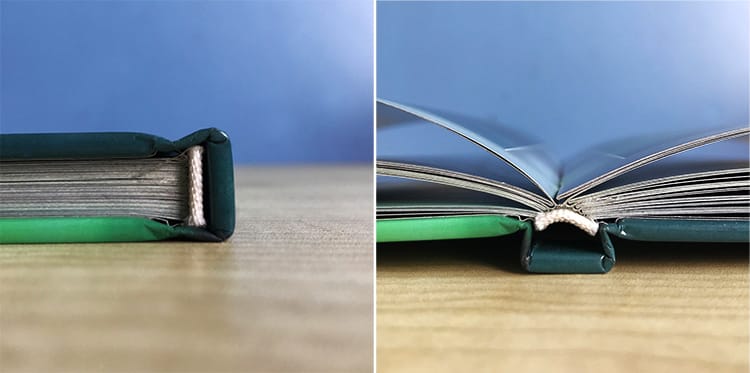

Board Book Binding | Side Sewn |

|

|

Extra thick cardboards are mounted together and usually finished with round corners. Pages are be able to layflat. | Side-sewn bindings are particularly well suited to children’s and photo books, as well as other thin-cased projects. As the name implies, a fiber thread is used to sew through the paper stack, which results in a secure binding. |

Some books just need that little something extra. From opulent cover finishes to those unique touches like end sheets, we can make sure your book stands out from the crowd. Imagining something you don’t see listed below? Get in touch to talk about your project!

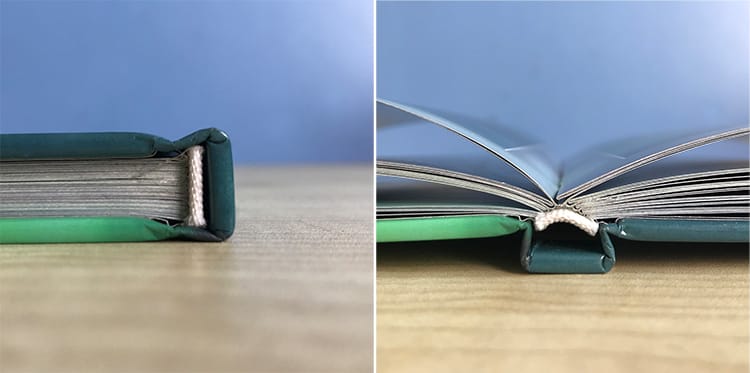

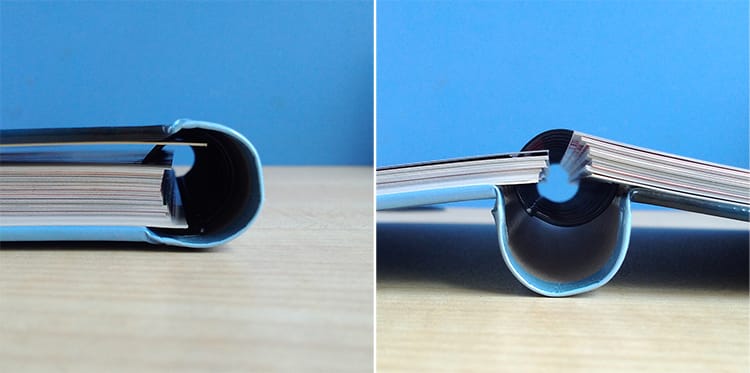

Headbands/Footbands |

|

These are narrow strips of cloth either sewn or glued to the top (headband) or the bottom (footband) of the book’s spine to add a finishing touch. |

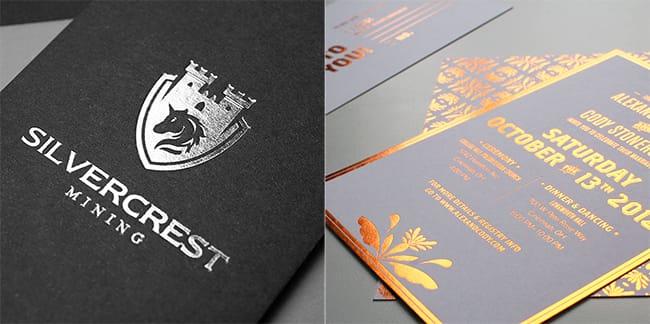

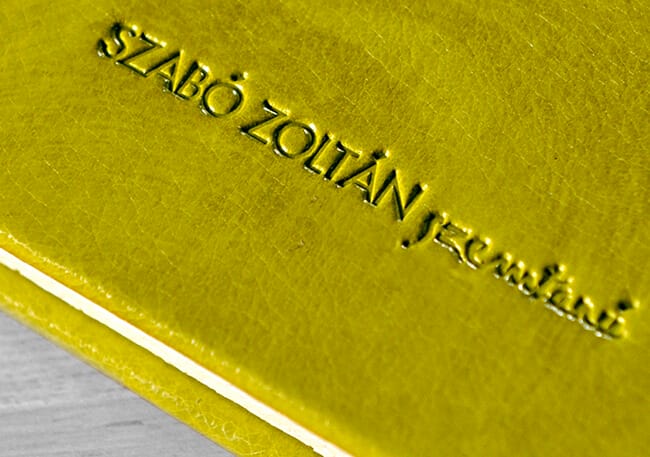

Foil Stamping |

|

Foil (often metallic, black, or white) is applied to the cover or spine using a heated die, leaving behind the design of your choosing. |

French Flaps |

|

Similar to a dust jacket but for softcover books, French flaps are a great place to include praise for your work. |

Embossing |

|

This is the process of creating a raised effect on the cover of a paperback book or dust jacket. Embossing can be used either for emphasis (e.g., raising the title) or texture (pictured above). |

Colored End Sheets |

|

Add a pop of color with end sheets (the first and last pages of the book) in a vibrant hue. |

Special Features

Some books just need that little something extra. From opulent cover finishes to those unique touches like end sheets, we can make sure your book stands out from the crowd. Imagining something you don’t see listed below? Get in touch to talk about your project!

Varnish

Varnish gives the pages a smooth texture and ‘seals’ the ink or toner. It can be glossy or matte and is mostly used

for high-quality reading material like coffee table books and for magazine covers. Definitely worth mentioning are

spot UV varnishes which are applied only to (a) limited part(s) of the page or cover and then cured by UV light

during the printing process, resulting in a glossy coating that adds texture and focal interest to specific areas

of the printing surface.

Lamination

Laminating a cover means adding a glossy or matte protective layer, making the surface (relatively) water resistant

and sturdier. Hence, this method is mostly chosen for softcover books. High gloss lamination is known to make

colors more vivid and images sharper. Matte lamination is more subdued, yet exudes luxury.

Foil stamping

Using heat and pressure, foil stamping is the process of applying a malleable metallic foil to specific areas of the print surface.

Embossing or debossing

Raising parts of the page or cover, e.g. a book’s title, to give it more texture is referred to as embossing.

Debossing, by contrast, indents parts of the page.

Home

Home

You May Also Like

You May Also Like

Tel

Tel

Email

Email

Address

Address